Termica Neo At Glance

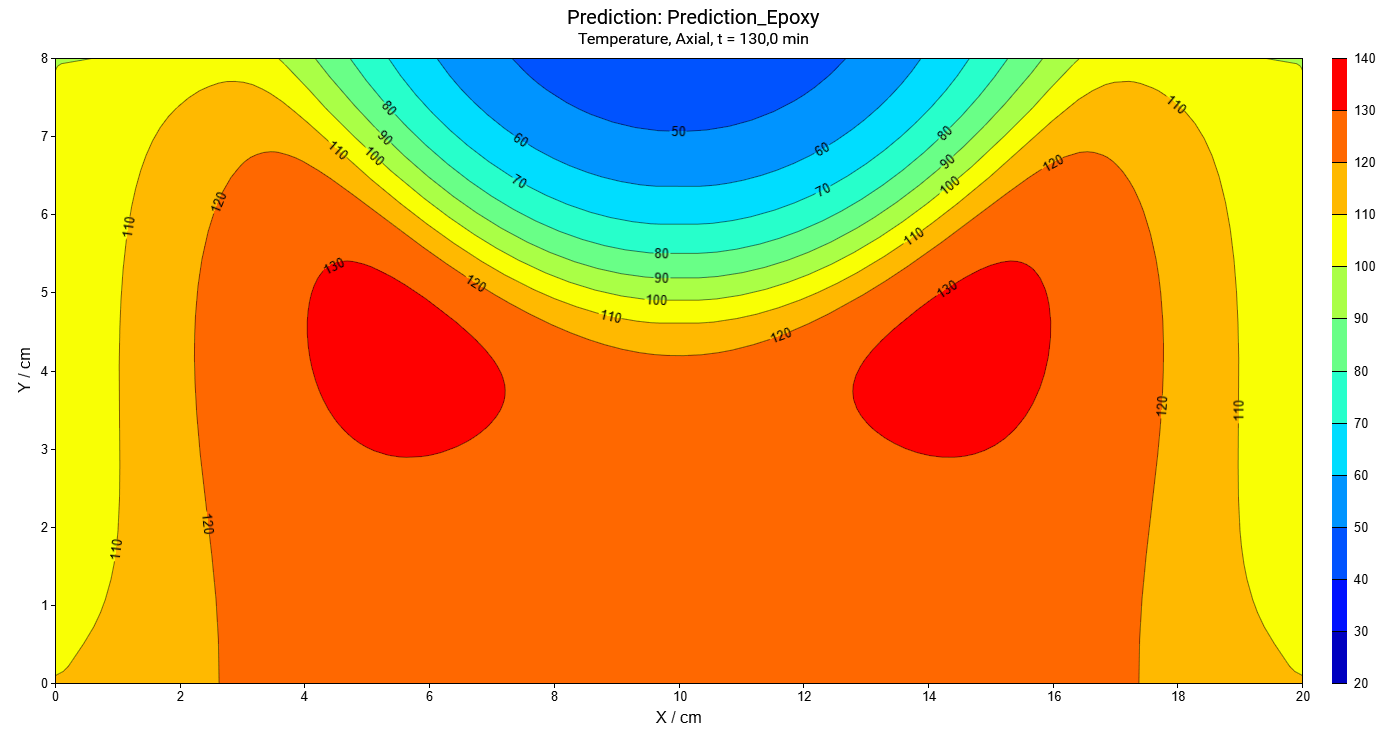

Termica Neo is a software for the simulation of the thermal behavior for chemical reactions and crystallization in solids or liquids in volumes with sizes from centimeters to meters. The main applications are storage, transport and production processes in chemical industry, where the temperature gradients in the reacting media are significant and must be considered. The software is used for solving the problems of thermal safety for materials with high thermal potential, as well as for simulation of industrial processes of curing, cross-linking, sintering and polymer crystallization.

Termica Neo web site: https://termica.netzsch.com

Termica Neo Software is completely compatible with NETZSCH Kinetics Neo Software (kinetics.netzsch.com) which has no limitations for the complexity of chemical process. Termica Neo is able for using of both model free and model-based kinetic approaches. For model-based approach there is no limitations for the number of individual reaction steps and for connections between them including independent, competing, or consecutive steps.

The simulation software accepts all kinetic parameters directly from the software NETZSCH Kinetics Neo for kinetic analysis of chemical processes, then uses additionally the temperature-dependent parameters like density, thermal conductivity, and heat capacity. Each external surface of the volume can contain the own material and thickness, the own surrounding material with own temperature profile.

The software provides time dependent and temperature-dependent results for temperature, concentration of all reactants and reaction rate in 2D and 3D view. The searching of Self Accelerating Decomposition Temperature (SADT) as well as the simulation for adiabatic conditions and infinite heat transfer to surrounding is also available.

Termica Neo can:

-

Simulate your material behavior at each point inside the container.

-

Determine the temperature, conversion, concentrations for a given time and position of the reactant inside the container.

-

Predict degree of curing, decomposition, crystallization.

-

Determine thermal safety conditions for production and storage like Self-Accelerating Decomposition Temperature (SADT).